RFT STEEL CEMENT PANEL

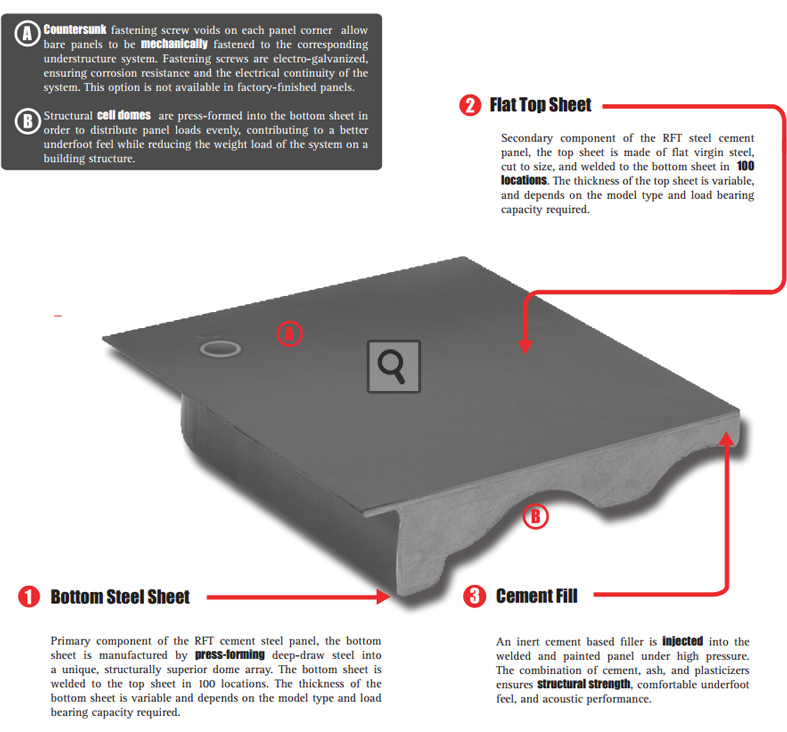

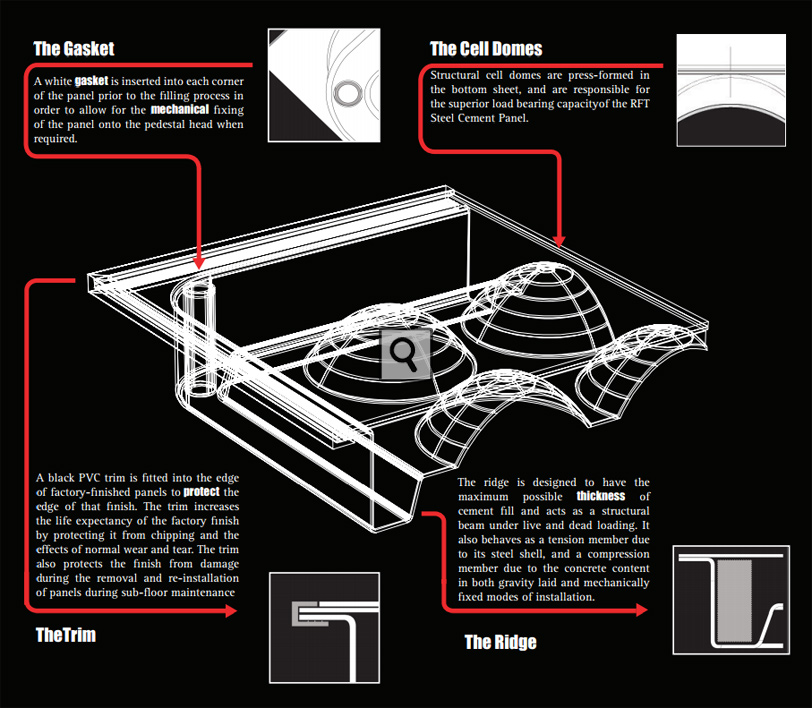

RFT manufactures steel cement raised access floor panels, also known as cementitious floor panels, for all types of applications. The range of use includes general office spaces, computer and control rooms, as well as industrial applications. The main characteristics of these panels are structural strength, resistance to fire and humidity, and solid and quiet underfoot feel. Panels are manufactured by welding together a press formed deep-draw bottom sheet and a flat top sheet. The panel is then trimmed, phosphate washed, and polyester powder coated. It is subsequently injected with a cement fill and allowed to cure for 72 hours. Panels can be installed on either Cross-Head or Stringer Grid understructure systems to achieve finished floor heights ranging from 70mm to 2000mm.

THE PANEL IN DETAIL

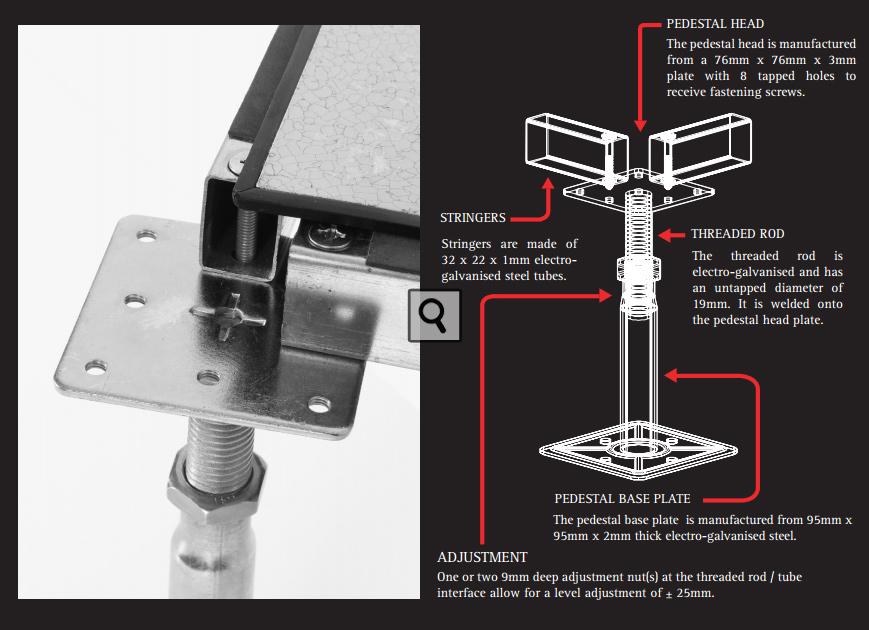

RFT UNDERSTRUCTURE SYSTEMS

The Stringer Grid System

The Stringer Grid System

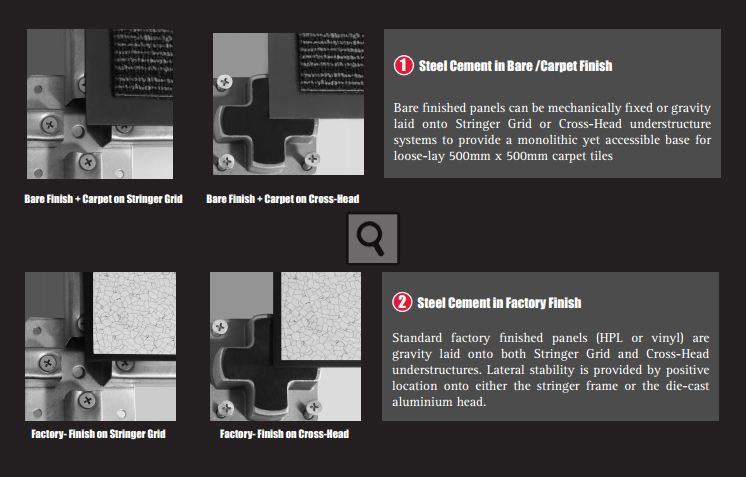

For steel cement panels, RFT offers two types of understructure systems to cater for all heights, load performance requirements, and applications. RFT steel cement panels are interchangeable within the two understructure systems.Used in all applications, the Stringer Grid system is especially recommended for greater finished floor heights and heavy duty applications. Stringers are mechanically fastened onto the pedestal head thus providing a monolithic frame into which the panels are inserted. For further strength, bare panels may also be mechanically fastened onto the pedestal heads. This system ensures improved rigidity and lateral stability, as well as a superior underfoot feel. Panels are easily interchangeable within each stringer frame without the need for any alterations in the system.

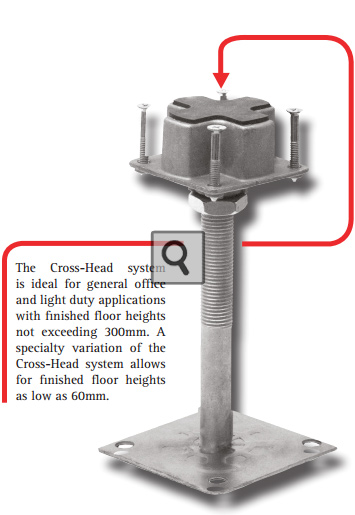

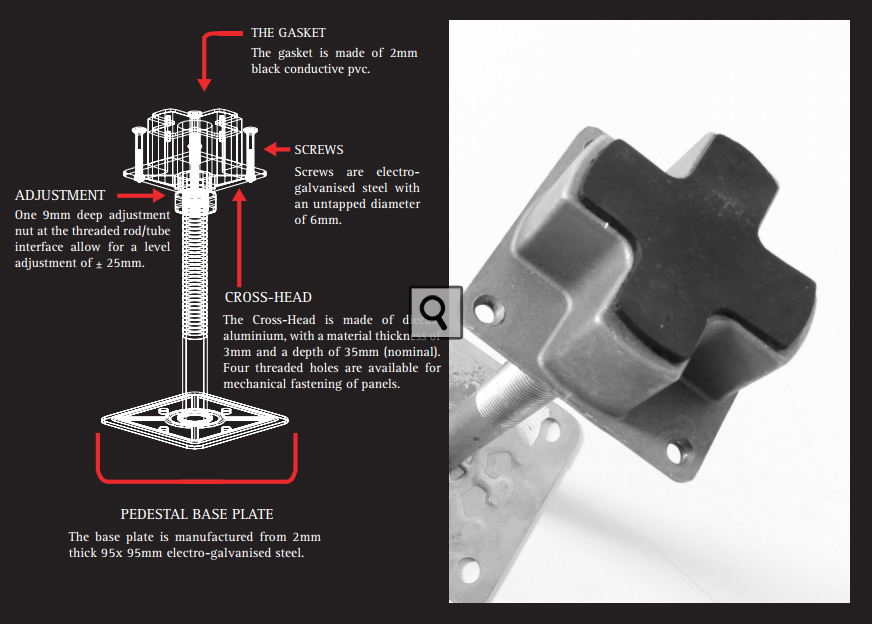

The Cross-head System

The Cross-head System

Utilising a unique die-cast aluminium head that offers positive location of the panel corners onto the pedestal head, the Cross-Head system is recommended for areas of low finished floor height where extensive sub-floor services need to be installed. The stringer-less Cross-Head system offers the same ease of installation and maintenance, as well as increased unobstructed access to all sub-floor services. Electrical continuity and quiet underfoot performance are achieved with the use of a black conductive pvc gasket placed between the panels and the understructure head.

INTERFACE